SKC

-

CCorporation

A leading company that strive for the world’s best.

A leading company that strive for the world’s best.

-

CCreation

Global ESG material solutions company

Global ESG material solutions company

-

CCommunication

SKC is making efforts to create a better future for all of our partners.

SKC is making efforts to create a better future for all of our partners.

-

CCareer

SKC is making efforts to create a better future for all of our partners.

SKC is making efforts to create a better future for all of our partners.

홈CreationIndustry Material Business

The fourth largest PET film maker in the world

Since the first development in 1977 of the polyester (PET) film in Korea,

SKC has been constantly enhancing its products and increasing quality through research and development.In 1980, SKC was the fourth company to develop colored videotape, which was followed by companies in the US, Germany, and Japan, and was recognized as a dominant market player. Presently, SKC has a production system which covers the process of polymerizing polyester and converting base film.

As the world’s third largest PET film manufacturer, SKT produces various types of films such as ▷ optical film ▷ packaging film ▷ industrial film ▷ graphic film ▷ solar film, etc.

Film production flowchart

- High penetration rate, uniform thickness and excellent printability

-

SKC’s film is highly acclaimed by clients as it has excellent transparency, uniform thickness, and outstanding printing properties. Popular products include optical film used for LCD displays. Various PET films are also used in LCD display such as reflective film and polarizer protective film, etc. SKC’s products have excellent properties such as passing, gathering, diffusing and reflecting lights.

The shrinkable film, a packaging film, is the second product in the world that SKC succeeded in mass production. It not only has excellent basic properties as a packaging film, but it is also an eco-friendly product that can be recycled with no harmful substances created when burned. The high transparency film among the graphic films provides excellent transmittance, and since it contains no foreign substance, it is mainly used as anti-spattering films inside the display screen of mobile phones and as medical X-ray films.

SKC is also the world’s first manufacturer of all film products (PET film, fluorine film, and EVA sheet) required for solar cells. EVA sheet is a film that protects the wafer, a core part of the solar cell, whereas PET film and fluorine film constitute the ‘backsheet’ that protects the back of the solar photovoltaic powder generation module.

-

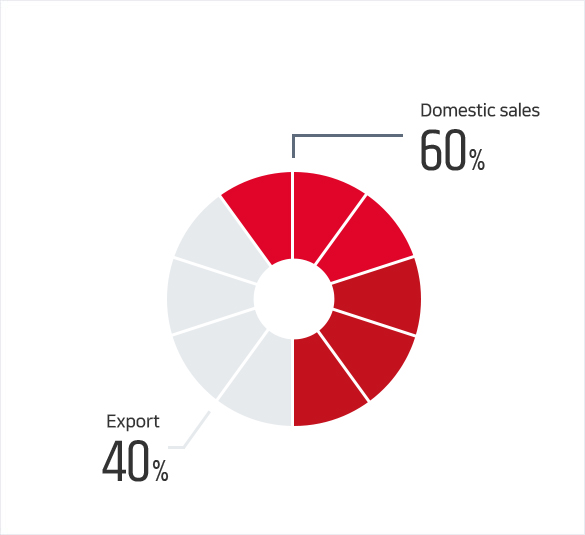

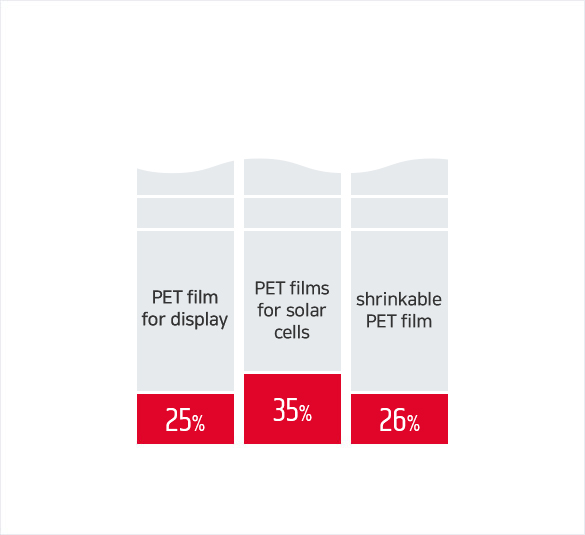

Proportion of sales

-

World market share of SK Film

-

World’s 4th largest PET Film Maker based on production capacity

22 tons PET FILM

22 tons PET FILM -

Size of workplace

Suwon Plant165000 ㎡

Jincheon Plant330000 ㎡

SKC Inc.958000 ㎡

SKC Jiangsu.165000 ㎡

Suwon Plant165000 ㎡

Jincheon Plant330000 ㎡

SKC Inc.958000 ㎡

SKC Jiangsu.165000 ㎡

- PET Film Maker with more than 40 years of film technology competence

-

At present, SKC strives to develop high-value-added products based on its film technology competence which has been accumulated for over 30 years. A typical example is the transparent polyimide film (transparent PI film) which can be bent, twisted and will replace glass used for display screens. Although it is transparent and thin, it is strong, flexible, unbreakable and can be folded and unfolded without being damaged. This product has high potential for growth as it can be applied to foldable products, rollable products, as well as wearable products like clothes.

SKC is also focusing on polyvinyl butyral film (PVB film) used in automotive and construction, and are mainly imported. PVB film is an essential safety film used to protect people in the event of an accident. It is located between glasses, holding the glass pieces together when the glass breaks, so that it does not splinter and spatter. This will enhance the high-value-added specialty products.

SKC is actively engaged in the film converting business. In June 2017, SKC took over SKC Haas Display, the top film converting company in Korea, changing its name to SKC hi-tech & marketing. SKC is making various efforts to add its own film manufacturing technology and R & D capability to SKC hi-tech & marketing, and is looking to expand facilities so as to allow the technology of SKC hi-tech & marketing to shine.

-

First in the world 1st

Developed PET film

Developed videotape

Developed LCD polarizer protective film

Developed shrinkable film

Developed polyimide film

Developed eco-friendly bio-compostable film -

First in Korea 1st

Developed polyester twistable PET film

Developed environmentally friendly bio-compostable film

Commercialized super molecular transparent electrode film