NEWS

SK nexilis’s copper foil certified as the longest, widest, and thinnest ever made in the country by KRI

Sheer technological prowess proved with the production of a 56.5 km long, 4.5㎛ thick, 1.33 m wide copper foil in 4 days

Production capacity enhanced ∙∙∙ strengthening the position as the world’s No.1 copper foil manufacturer

SK nexilis (Representative Kim Young-tae), in which SKC (President Lee Wan-jae) invests, has set a record in the production of copper foil, which is a core part for EV batteries, with an extremely long copper foil, with a thickness equal to one-thirtieth of a hair. The Company made this length of copper foil without stopping over the span of four days, and had the record certified by the Korea Record Institute (KRI). SK nexilis plans to enhance its production capacity that befits its technological prowess as the world’s No.1 copper foil manufacturer.

On October 20, SK nexilis’s factory in Jeongeup had its product certified as the longest (56.5km), widest (1.33m), and thinnest (4.5 ㎛)one ever made in the country by KRI. That particular length of copper foil was made on June 11-14, 2019.

KRI’s certification was confirmed as the new official best record _ base_d on the following data/materials submitted by SK nexilis: purity test results, videos of the scene of the production and measurement, a third-party letter of confirmation, a summary report on measured figures, challenge records, an executive summary, the media’s independent evidence, etc.

Thinner copper foils help battery manufacturers make lighter batteries with a higher capacity. Long, thin copper foils lead to a higher productivity of customer businesses. The production of thin and wide lengths of copper foil requires an exceptional level of technology. Thinner copper foils are likely to be torn and sensitive to wrinkles. SK nexilis has maintained its position as the world’s No.1 in terms of technological prowess. In 2013, it became the world’s first manufacturer engaging in the mass production of copper foil as thin as 6㎛. It broke its own record with the production of one as thin as 5㎛ in 2017. In 2019, it broke its own record, once again, with the mass production of a 4㎛-thick copper foil, which was 30 km long.

Last July, the Company received the Presidential Prize of the 2019 IR (Industrial Research) 52 Jang Young-shil Award, in recognition of technological excellence in the manufacturing of a copper foil for a high-capacity lithium secondary battery. As for the said award, an item with the best technology is selected each week, and the Presidential Prize is presented to the best of the best at the end of each year.

SK nexilis is expanding its production capacity that befits its status as the world’s No.1 copper foil manufacturer. Early this year, it completed the work for a fourth factory in Jeongeup, which brought its production capacity to 34,000 tons a year. It is now building its fifth and sixth factories. Its total annual production capacity will be increased to 52,000 tons with the completion of these factories by early 2022.

SK nexilis is also making preparations to make forays into global markets. It plans to finalize the locations within this year and to start building the first production facility out of the country, with the aim of increasing its production capacity three/four-fold by 2025.

Commenting on the matter, SK nexilis Representative Kim Young-tae said, “In addition to the KRI’s certification made for us, we will have our name listed in the World Record Committee (WRC) and the Guinness Book of World Records. We will continue to strive to strengthen our status as the world’s No.1 copper foil manufacturer on the back of a sense of confidence in our sheer technological prowess.”

[Referential photos]

[SK nexilis’s factory in Jeongeup, Korea]

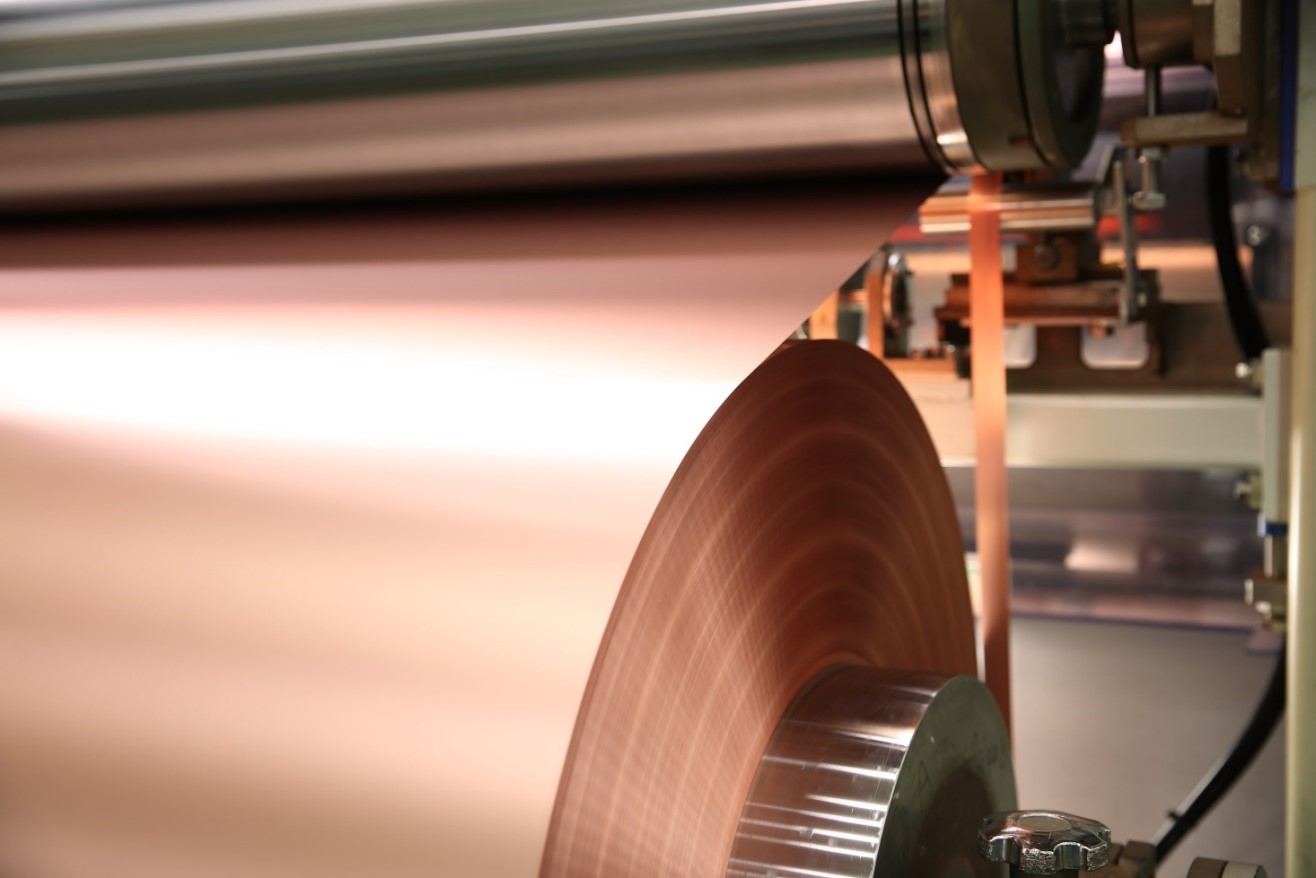

[Copper foil being made by SK nexilis]