NEWS

MOU on technical partnership for commercialization with a Japanese venture company boasting of advanced technology··· large-scale recycling of waste plastic possible

Goal of securing commercialization technology until 2022··· Commercialization to be promoted in the SK picglobal Ulsan Plant by 2023

SKC (CEO Lee Wan-jae) is signing an MOU on a partnership with a Japanese venture company boasting of advanced technology to initiate the eco-friendly recycling business with waste plastic pyrolysis oil. At present, pyrolysis oil such as crude oil is extracted from waste plastic for use in the boiler; in the long term, however, the goal is to succeed in purification to develop the ingredients for plastic. SKC signed an MOU with Ulsan Metropolitan City on the waste plastic recycling system last December to search for methods of initiating the business.

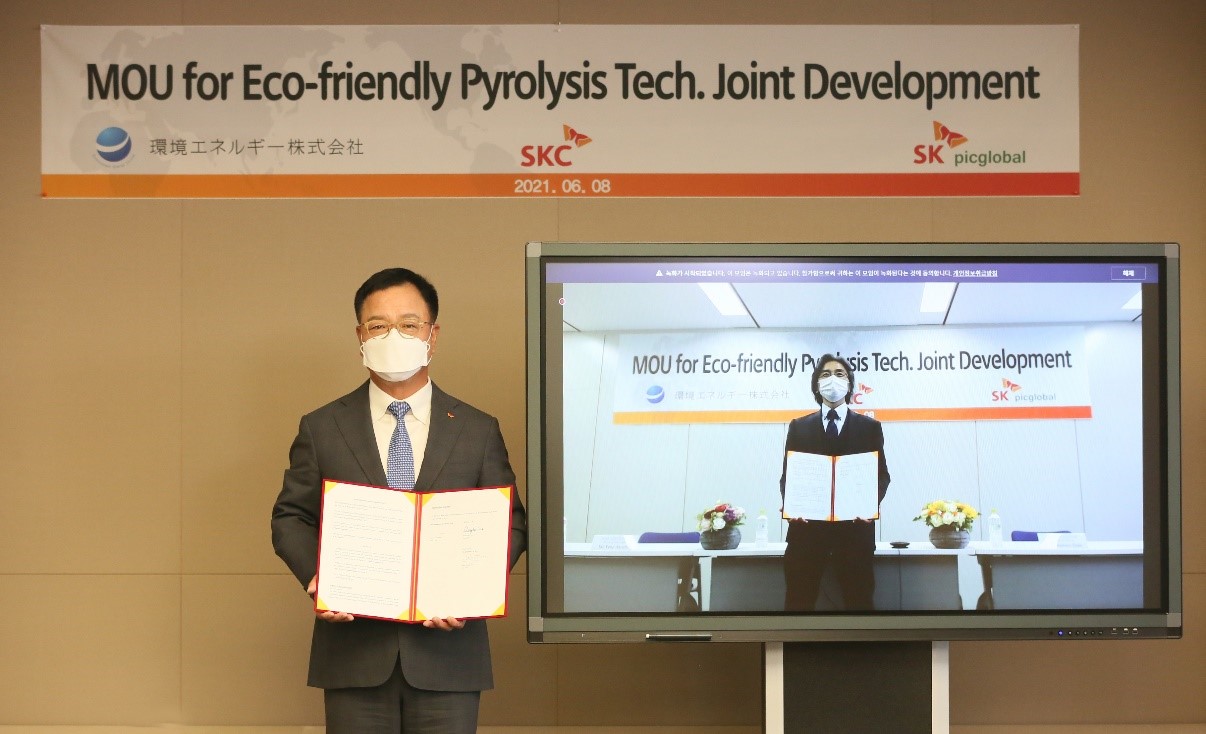

SKC held a videoconference with Kankyo Energy (Environment Energy in Japan on the 8th to sign the MOU on cooperation for technical development for the commercialization of pyrolysis on waste plastic. Two companies agreed on joint ownership of the technology and secured an exclusive license. SKC will add the know-how of the chemical business of SK picglobal (Investment Company) to the advance technology of Kankyo Energy for installing the pilot facility until this year and secure commercialization technology until the first semester of next year. The goal is to enable commercial operation by 2023.

Out of the current global annual use of 350 million tons of plastic, only about 15% is being recycled. Most of the waste plastics are incinerated, buried, or thrown into the ocean. Since SKC commercialized the eco-friendly biodegradable PLA film for the first time in the world, the company has searched for methods to overcome the difficulties of import prohibition executed in China in 2018. In 2019, SKC became the first Korean company to become the member of “AEPW (Alliance to End Plastic Waste)” participated in by global companies such as BASF SE, etc., and review the relevant technologies.

The pyrolysis technology on waste plastic has high usability in terms of recycling plastic such as waste vinyl, etc. However, recycling is performed centering on a single material, so it is difficult to perform recycling when the plastic is mixed with various materials; classification must also be made according to the types and colors. Various types of plastic can be recycled without classification when the pyrolysis technology is applied, thanks to the method of extracting the pyrolysis oil by applying heat. This increases the level of recycling.

Meanwhile, the pyrolysis technology on waste plastic is still in the initial stage globally. SKC is continuing the challenge of large-scale commercialization for the first time in Korea centering on the capability of SK picglobal, which succeeded in the world’s first commercialization of eco-friendly HPPO technique. Especially, the pyrolysis technology of Kankyo Energy in Japan has higher productivity compared to other pyrolysis technologies, and the facility operation rate is also high enough for commercialization.

SKC and SK picglobal are planning to install the pilot facility in the SK picglobal Ulsan Plant in partnership with Kankyo Energy. The commercialization technology optimized for domestic waste vinyl will be secured until 2022, and the commercialization facility will be installed in the Ulsan Plant with the goal of initiating operation until 2023. After newly constructing the plant, 5 or more tons of waste plastic such as waste vinyl, etc. will be used to produce over 35,000 tons of pyrolysis oil.

The pyrolysis oil will be used as fuel for the boiler in the SK picglobal Ulsan Plant for now, but the level of removing the impurities will be increased in the future to promote the method of using pyrolysis oil as high value-added plastic ingredients, and this will enable the circular economy of producing plastic with waste plastic. Especially after the commercial operation, the method of expanding the business globally through cooperation with the joint partner of Kuwait PIC will be reviewed.

“SKC is developing the eco-friendly material business along with mobility and semiconductors as the future growth engine. It will continue to cooperate with partners in efforts for establishing a virtuous cycle system of large-scale recycling of waste plastic, which was difficult to process in the past, and to contribute to the environment,” SKC personnel said.

[In the videoconference held on the 8th, SKC signed the MOU with Kankyo Energy in Japan to initiate the eco-friendly business with waste plastic pyrolysis oil. Image of Lee Wan-jae, CEO of SKC (Third from left), and CEO Shuji Noda of Kankyo Energy (Second from right).]